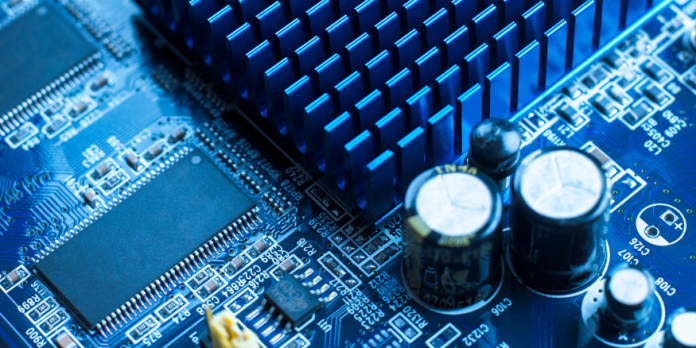

The implementation of appropriate thermal regulation is paramount to ensure sustained efficacy and dependability. One of the most efficacious techniques for temperature management in electronic devices is the utilization of heat sinks. In this article, you’ll have a comprehensive examination of electronic heat sinks and their significance in the management of thermal dynamics.

What are Heat Sinks?

The heat sink works by providing a large surface area to transfer heat from the electronic component to the surrounding air. Heat sinks are available in manifold configurations and dimensions, and they are conventionally constructed from substances exhibiting high thermal conductivity, such as aluminum or copper.

Customizing Heat Sinks for Specific Applications

In some cases, it may be necessary to customize a heat sink to ensure optimal performance and fit within your device. Customizing a heat sink involves tailoring its design to the specific thermal requirements of your device.

To enhance the heat sink’s thermal performance, this can entail changing its size, shape, or fin density. Using different materials or coatings may also be necessary to improve the heat sink’s longevity or performance.

Importance of Heat Sinks in Thermal Management

Heat sinks play a crucial role in thermal management of electronic devices. As electronic component’s function, they produce a prodigious amount of thermal energy, and if this energy is not optimally managed, it may culminate in operational malfunction or even outright failure of the components.

Heat sinks help to prevent this by absorbing and dissipating the heat generated by electronic components. This helps to keep the components operating within their safe temperature range, ensuring long-term performance and reliability.

Types of Heat Sinks

An assortment of heat sink variants exist, each uniquely fashioned to suit a particular purpose. A few examples of these include:

Finned Heat Sinks: This type of heat sink is characterized by the presence of fins that augment the surface area available for the dissipation of thermal energy. Finned heat sinks are suitable for applications that require high heat dissipation.

Pin Fin Heat Sinks: These heat sinks feature pins that increase the surface area for heat dissipation. They are suitable for applications that require high-density packaging.

Bonded Fin Heat Sinks: These heat sinks feature fins that are bonded to the base using a thermal adhesive. They are suitable for applications that require high thermal performance.

Extruded Heat Sinks: These heat sinks are made by extruding aluminum or copper to create a complex shape with fins. They are suitable for applications that require a customized shape.

Liquid Cooled Heat Sinks: These heat sinks use liquid to absorb and dissipate heat. They can function at high temperatures and are appropriate for applications requiring great heat dissipation.

Choosing the Right Heat Sink

Choosing the right heat sink is crucial for effective thermal management. When selecting a heat sink, factors such as the application, power dissipation, size, and mounting requirements must be considered.

Conclusion

In conclusion, heat sinks play a crucial role in thermal management of electronic devices. Heat sinks play a pivotal role in engendering longevity and dependability of electronic components by absorbing and dissipating the thermal energy generated during operation.

The availability of several types of heat sinks, each optimized for a particular function, enhances their versatility. With optimal thermal regulation, electronic devices can function at their peak potential and furnish extended reliability to users.