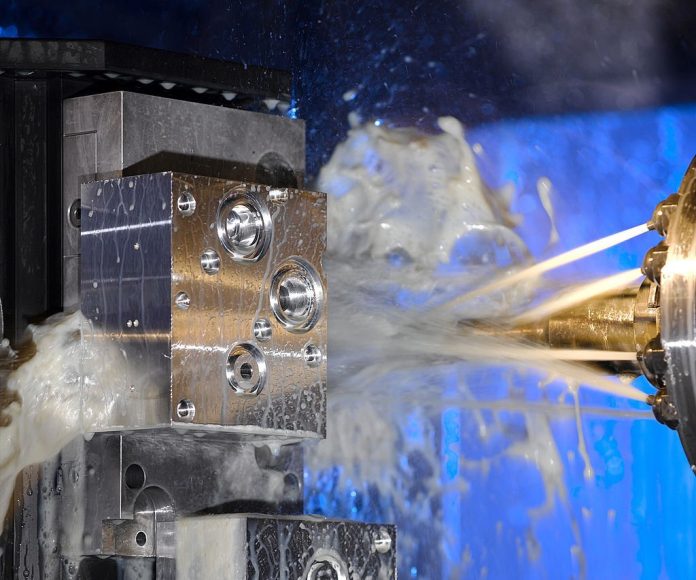

All over the Internet, there are many talks about aluminum machining that has people talking. Innovation has saved a lot of time and stress by creating machines that make machining aluminum a lot easier. All you need to do is understand how the machine works, and you’ll have your aluminum in the right shape. One of the numerous machines that have brought a lot of ease to aluminum machining is the CNC machine. CNC machine stands for computer numerically controlled machines, and as the name implies, these machines rely totally on computerized programs to work. Most of the other devices used in aluminum machining require a lot of your input. For instance, let’s assume you want to cut aluminum with a manual Lathe Machine. You will need to consciously control the machine to cut the aluminum properly. But with a CNC machine, you have more business handling the machine while it works.

The CNC machine only requires you to do two things; understand the machine working process and set up the CNC device to work appropriately. The CNC program already specifies how the machine will work and what you need to set up. After that, you need to understand the programs well to use it accordingly. Most CNC work with the CAD and CAM segments. The CAD segment is the design category, and the focus is to visually represent what you want to produce. The machine designs the prototype clearly, showing errors you need to fix. After getting your design right, your CNC machine can commence work immediately through the right programs. The ease of using a CNC machine has made it admirable globally. Thousands of people want to own a CNC machine if they can afford one, while others want to hire a CNC machine contractor to make the job easy. This gives a lot of opportunities I

In the CNC machinery business. This guide will discuss the pros and cons of starting a CNC machine business.

Pros

Some of the pros of CNC business includes;

Making money

Profit is the sole reason why we start the business. Yes, we may have a little bit of passion and other reasons the business starts, but making money is a huge part of it. When you launch a CNC business, there is a high chance of profit. The profits usually come in large quantities.

Ready customer

When you are selling clothing items, everyone is literally your customer, regardless of the cloth type you’re selling. However, with a CNC machine, not everyone is your customer. But when you can identify your customer, the customer is usually ready to buy or hire you instantly. There is not much competition, so there is no need for excess persuasion.

Long-term business

Whether you are into the sale of CNC machines or you help companies with CNC machining, you will be in the business for a long time.

Cons

The cons of starting a CNC business are mainly the cost. To start the business initially, you have to buy a lot of tools and the machine itself. Therefore, you will need high capital. Also, if the machine spoils, you may need a replacement part and a great pro to fix. Consequently, it has some high running costs.