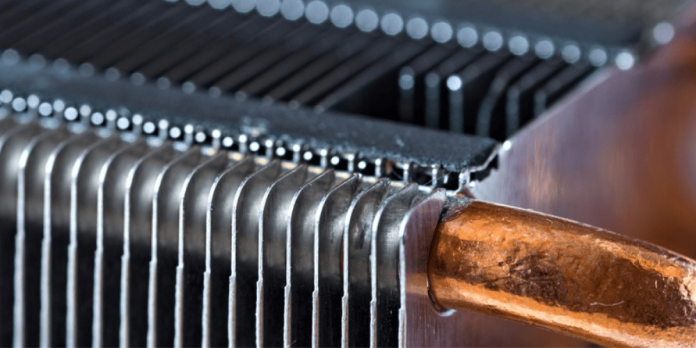

Extruded copper heat sinks can be more environmentally sustainable compared to other types of heat sinks due to several factors:

- Recyclability: Copper is a highly recyclable material, with over 80% of copper products being recycled globally. This means that copper heat sinks can be recycled at the end of their lifecycle, reducing waste and conserving natural resources.

- Energy efficiency: Extruded copper heat sinks are typically more energy-efficient than other types of heat sinks, as copper has a high thermal conductivity, which means that it can absorb and dissipate heat more quickly and efficiently. This can lead to lower energy consumption and reduced greenhouse gas emissions.

- Durability: Copper is a highly durable material, which means that copper heat sinks can have a longer lifespan compared to other materials. This can reduce the need for frequent replacement, which in turn reduces waste and conserves resources.

- Production process: The production process for extruded copper heat sinks is generally more environmentally friendly compared to other types of heat sinks. The extrusion process typically uses less energy compared to other manufacturing processes such as die-casting, and there is typically less waste generated during the production process.

Overall, extruded copper heat sink can be a more environmentally sustainable option compared to other types of heat sinks due to their recyclability, energy efficiency, durability, and production process. However, it is important to consider the entire lifecycle of the heat sink, including the sourcing of raw materials, the manufacturing process, and end-of-life disposal, to ensure that the heat sink is produced and used in an environmentally responsible manner.

Extruded copper heat sink in laptop and similar appliances

Extruded copper heat sinks can be a suitable choice for use in laptops and similar appliances due to their high thermal conductivity, compact size, and ease of manufacturing. Laptops and similar devices generate a significant amount of heat, which can lead to reduced performance and even damage to internal components. Using a copper heat sink can help to dissipate this heat efficiently and keep the device running smoothly.

Extruded copper heat sinks are typically lightweight and can be formed into complex shapes, making them a good fit for laptops and other small electronic devices that have limited space for heat dissipation. Additionally, the extrusion process used to manufacture copper heat sinks is generally more cost-effective and produces less waste compared to other manufacturing methods, which can help to keep the overall cost of the device down.

However, there are some potential drawbacks to using copper heat sinks in laptops and other small electronic devices. Copper is heavier than other materials such as aluminum, which can add weight to the device. Additionally, copper heat sinks can be more expensive than other types of heat sinks, which can impact the overall cost of the device.

Overall, the choice of heat sink material for a laptop or similar appliance will depend on the specific requirements of the application, including performance, size, weight, and cost. Extruded copper heat sinks can be a suitable option for many applications, but other materials such as aluminum may also be appropriate depending on the specific needs of the device.