Trying to produce a prototype quickly can be expensive, and it isn’t easy to get your idea out there without a physical product. Machining is the only way to go when you want to build prototypes quickly and affordably.

But good manufacturing services are hard to come by, with delays and poor quality finishes.

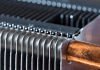

The CNC machining service is machining the shape of the object with numerical control tools. A CNC machining service is a cutting machine that operates on computerized numerical control principles.

The machines operate by receiving commands through the programming devices, coordinate systems, and the critical paths of movement. They produce some identical parts simultaneously, even with highly complex geometries and shapes.

Benefits Of CNC Machining Service

The benefits of the Service of CNC Machining are as follows: It allows you to have a unique product manufactured according to your specifications. It also allows you to make the production process more efficient by combining several operations.

It reduces your lead time and saves money. Some other general benefits of CNC machining service are associated as:

· High Results Production Than Manual Machining

CNC machining service is cost-effective and efficient compared to manual machining. The results you get will be much better because there is no need for effort from your end, and it will be less time-consuming.

In other words, you can use numerical control equipment to make it easy for us to complete a complex workpiece. After it is done, you will see that the original shape, which you cannot do manually, will be significantly improved.

· Automatic Update For Latest Programming

CNC machining service provides all the possibilities for producing machined parts. It is automated machinery and all the latest software, which allow you to quickly and efficiently process orders in any volume.

To ensure the opportunity to serve your customers in the best way, we created an automatic updating program system. You need to wait for the machine to restart after turning it on.

· Works Without Hassle Of Staffing Shortages

CNC machining works without staff. How does he do it? Because the machine does everything for you. Your job is to load raw material into the machine and load parts that have been machined out of the machine.

The CNC machining will work all day long if you want it to. It means that you get high-quality machined parts without paying premium prices for staff.

· Needs Less Maintenance

CNC Machining Service will give you a perfect life after the purchase, saving you lots of costs. The service life is longer than that of other products in the market. Since this type of machining involves less human interference.

It costs less and is more accurate than other machining processes. As long as these digital models are appropriately designed with simple geometries, they can be offered no maintenance during production by any other human hand.

· User-Friendly Interface

CNC machining offers a user-friendly interface means the system is easy to use. Instead of having to call or wait for someone to answer emails. CNC machining users can operate their machines more effectively and efficiently.

It helps companies optimize processes such as inventory management and production scheduling; while improving customer service, thereby saving costs and increasing profits.